Top 10 Amisulpride Tablet Brands In India

Top 10 Amisulpride Tablet Brands In India: Amisulpride tablets are a core drug that is used in the treatment of psychiatric and mental health illnesses, especially schizophrenia. Cariprazine is an antipsychotic medication which targets some of the neurotransmitters in the brain and is therefore useful in treating symptoms like delusions, hallucinations, and disorganized thinking. Through regulation of mood and enhancement of cognition, Amisulpride plays a very big role in boosting the well-being and life satisfaction of people with psychotic disorders.

Amisulpride tablets are manufactured by several players in India, and all of them adhere to quality and efficacy standards. These brands offer Amisulpride in different forms and packages and are manufactured according to the top standards of production and regulatory requirements. These Top 10 Amisulpride Tablet Brands In India are popular among healthcare practitioners for the treatment of schizophrenia and other related diseases meaning this drug plays a crucial role in the treatment of mental disorders.

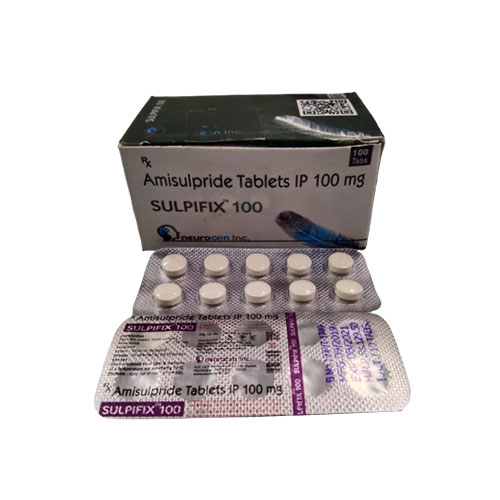

SULPIFIX 100 | Amisulpride 100 mg

Neurocon Inc. employs strict QC measures in the manufacture of SULPIFIX 100 throughout the production process. The formulation can be subjected to accurate dosing and dissolution analysis to determine batch-to-batch variability. To ensure that there is no compromise in the chemical composition and the effectiveness of the drug, instrumental analytical methods like HPLC are employed to analyze the API. During the formulation of the tablets, the team ensures they operate in a clean environment; while packing the medication in blisters of 10×10 size, proper examination is conducted to prevent humidity, contamination, and exposure to light.

AMPRIDE-200 | Amisulpride Tablet IP 200 mg

Dellwich Healthcare LLP has integrated the latest equipments and automation while manufacturing the AMPRIDE-200. The first step involves choosing highly pure Amisulpride and then blending them under set conditions. Their teams follow GMP rules to the latter, with particle size distribution as a major area of concentration to achieve bioavailability of the drug. They all pass through several in-process control checks such as Microbial testing and tablet compression. Lastly, blister packaging takes place in a clean room to minimize contamination while all packaging media are checked for stability.

EMIPRIDE 200 | Amisulpride 200 mg Tablet

At Elikem Pharmaceuticals Pvt Ltd, EMIPRIDE 200 undergoes a series of procedures to ensure that the drug maintains its efficacy and effectiveness as it ages. The manufacturing team employs purified air and water systems and minimizes cross-contamination hazards. This ensures that tablets have the right hardness, dissolution profile, and disintegration to ensure that the API is released as planned. The blister packaging is properly sealed under vacuum to protect it from the environment and oxidation.

AMIXIUS-50 | Amisulpride Tablets IP

Aloysius Biotech also conducts stability studies on the product, AMIXIUS-50, to determine its efficacy despite changing storage conditions. The production of Amisulpride involves granulating the product using precision methods and then tabulating it to enhance stability and reduce the bitter taste of the active ingredient. Quality control involves checking each production process for contamination; the blister packaging process is conducted under a certain temperature to enhance the product’s shelf life.

VINPRDE-400 | Amisulpride Tablet 400 mg

VINPRDE-400, offered by Neuro Vision, follow strict formulation procedures to ensure that the product provides similar treatment effects every time and is amongst the Top 10 Amisulpride Tablet Brands In India. The company employs sophisticated tablet press equipment and prides itself in delivering the 400 mg dosage. Their team also undergoes several quality control measures of formulation such as weight variation, uniformity of content, and friability tests. When it comes to blister packaging, each tablet is protected for transportation and storage conditions because it is not affected by environmental factors.

MOPRIDE 200 | Amisulpride 200 mg Tablet

Lahar Pharmaceuticals also makes MOPRIDE 200 free from contamination and uniform in quality through high-tech methods of granulation and compression. Every process is checked and in-process examination involves checking for microbial activity and tablet hardness. After manufacturing, the tablets are checked for appearance and are then put in blister packs, which offer protection to the product against moisture and the effects of the environment.

AMPHYRIDE-100 | Amisulpride Tablets IP 100 mg

Gemed Lifesciences Private Limited pays attention to quality in the development of AMPHYRIDE-100, which is among the top 10 amisulpride tablet manufacturers in India. Their process involves strict validation checks, for instance, dissolution profiles of tablets, to confirm that the API is well absorbed. The machine used to mix and compress the ingredients is sophisticated enough to mix and compress the ingredients effectively so that the product retains its two-year guaranteed shelf life in blister packing.

RERIDE-300 | Amisulpride Tablets 50/100/200/300/SR 400 mg

RERIDE-300 manufactured at ARIPOLIS BIOTECH PVT LTD employs the controlled-release mechanism for higher concentrations of the drug so that the active substances can be absorbed slowly and continuously. The control and testing take place continuously at each step of manufacturing to prevent deviations in the dosage. Blister strip packaging is performed in a sterilized environment to maintain the stability of the drug and allow safe usage for the patient.

AMIPULSIDE 100 | Amisulpride Tablets IP 100 mg

Steris Healthcare practices a holistic approach to provide the highest quality for AMIPULSIDE 100. They use GMP standard facilities in producing the tablets to conform with the accurate dosing, uniformity, and purity. The physical characteristics such as friability and dissolution are conducted on the tablets available on the market to check on their efficacy. The blister packaging system is selected to protect the tablets from any contamination, humidity, or light.

AMIFACT-200 | Amisulpride Tablets IP 200 mg

Quality assurance and control methods used in AMIFACT-200 are stringent for Tanishq Life Care. Packaging materials are obtained from qualified dealers, and each lot is subjected to stability tests for the product’s shelf stability. It uses the latest technology in compression technology to ensure that the dosage principle is well maintained. Blister packaging ensures that the drug content remains safe from factors such as moisture and extreme temperatures as it is packed.